Read in Texas Co-op Power about how CoServ is using PA12, a polyamide pipeline material, on gas projects.

Texas Co-op Power | Read Online: www.coserv.com/media/texas-co-op-power

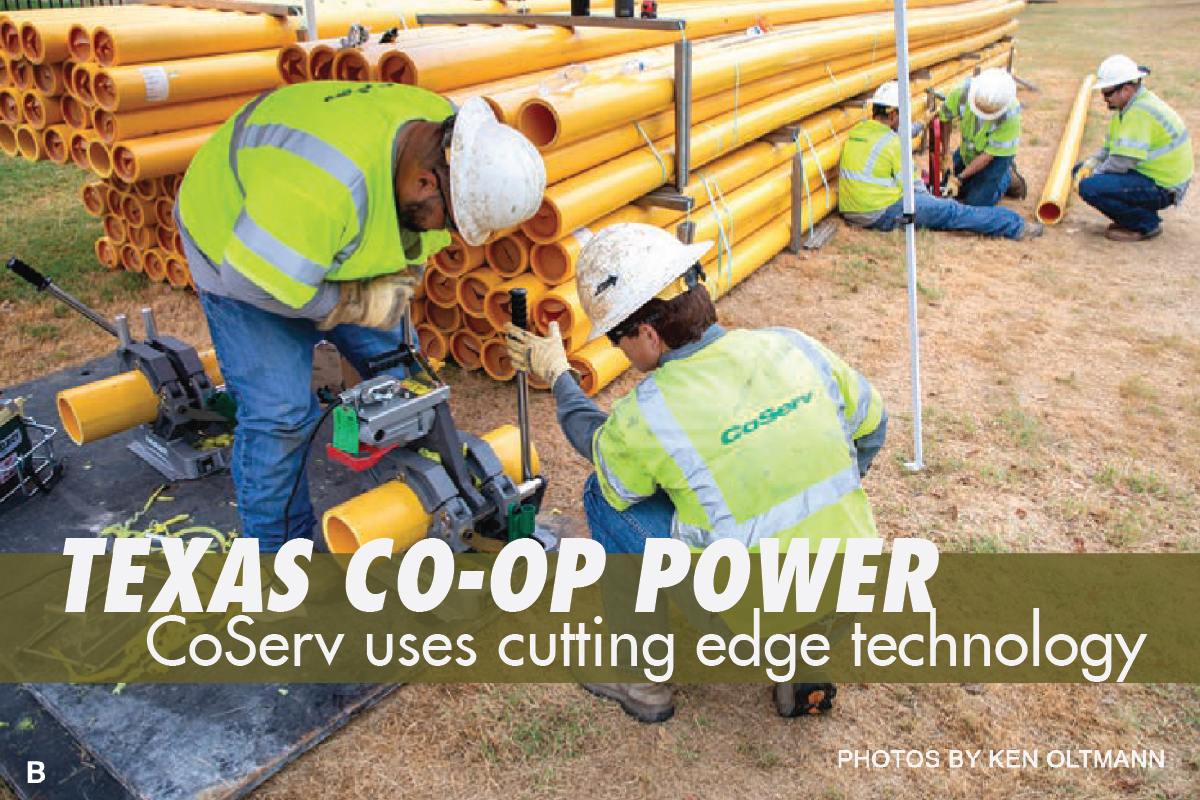

Story By: Nicholas Sakelaris, Photos By: Ken Oltmann

CoServ Gas will be among the first natural gas utilities in the country to use a new extremely durable material that requires fewer inspections, needs less maintenance and doesn’t require cathodic protection.

The plan is to replace an existing four-inch steel line that serves Lake Dallas, Corinth and parts of Denton with the new six-inch polyamide pipeline (commonly called PA-12) starting this year, said Rodney Hale, Director of Gas Operations.

“This new polyamide pipeline material and installation will have comparable cost to steel, but we will have long-term savings by using this compared to steel pipelines,” Rodney said. “PA-12 will ultimately be safer for the communities we serve, which is a critical part of our mission statement.”

Steel lines can carry up to 300-plus psi but require additional maintenance and inspections, which cost more money to maintain. Traditional polyethylene pipes couldn’t be used in these applications either because they can only carry a maximum of 60 pounds per square inch (psi).

PA-12 falls in the middle, as its maximum allowable operator pressure (MAOP) is 250 psi but it doesn’t conduct electricity so cathodic mitigation isn’t required, Rodney said. That means less maintenance costs.

Ryan Ellis, Director of Sales and Training for GROEBNER, said there’s been a gap in the industry because any pressure above what a traditional poly line can handle requires a steel line.

“PA-12 fills that gap, you can save a lot of money over the cost of steel,” Ryan said.

The difference, he said, is at the molecular level where, if you put it under a microscope, the molecules are packed tighter together than traditional polyethylene pipes.

The stronger bond means it’s less likely to rupture when hit by construction equipment than polyethylene lines.

Steel line repairs require assistance from contractors, which increases the cost. In the rare event that a PA-12 line is broken, CoServ Gas Technicians can repair it in-house with a process that’s similar to how they fix a poly line. The only difference is that they need hydraulic tools to pinch the line to cut off gas flow.

“Our first PA-12 project is the perfect example of CoServ’s commitment to excellence and Investing in Tomorrow,” Rodney said.