McElroy fusion machines, DataLogger, and Vault deliver precision, portability, and data-driven performance for smarter, safer projects.

McElroy continues to lead the way in fusion technology by pairing rugged, jobsite-ready machines with advanced tools that improve efficiency, consistency, and accountability. The latest innovations – like the TracStar® iSeries and Acrobat™ machines – integrate seamlessly with the DataLogger® and McElroy Vault™, giving operators real-time fusion data, compliance support, and proof of performance.

Alongside these solutions, McElroy offers a full lineup of small- and medium-diameter machines. From lightweight, hand-powered units for pipe as small as 1/2” CTS to versatile, track-mounted models handling pipe up to 18” OD, every machine is engineered for reliable fusion across a wide range of applications.

Through GROEBNER, you’ll find not only the right equipment but also the expertise to help you choose and operate it with confidence, ensuring every job is done smarter, safer, and more efficiently.

Automated, Data-Driven Fusion for Medium-Diameter

The TracStar® iSeries (412i & 618i for medium-diameter) is redefining medium-diameter fusion by delivering a new level of performance, reliability, and operator confidence. Building on the TracStar’s reputation for durability, the iSeries introduces smarter technology designed to enhance efficiency and consistency on the jobsite.

Integrated, software-controlled options – including a fully automatic mode – improve operator consistency and ensure adherence to standards, while built-in fusion record gathering enhances quality control and compliance. Numerous upgrades strengthen the platform while keeping it rugged and jobsite-ready, including emission-compliant engines and a range of hydraulic, mechanical, and electrical improvements. By combining intelligent technology with proven durability, the iSeries meets today’s challenges while advancing the future of fusion.

- FusionGuide™ Control System: Provides three levels of control – from operator-driven to fully automatic – reducing errors and making the fusion process more productive.

- Built-In DataLogger®: Captures every fusion, creating detailed records to verify quality and compliance with industry standards.

Data-Driven Fusion for Small-Diameter

As the industry moves toward smarter, data-driven fusion, McElroy ensures that smaller diameter applications can also generate accurate fusion records. The Acrobat™ fusion machines combine a compact, versatile design with full DataLogger® 7 compatibility, enabling operators to capture data for every joint. This integration provides real-time analysis and proof of fusion integrity, helping you maintain quality control and demonstrate compliance.

Among the available models, the Acrobat™ 180 is engineered for flexibility in confined spaces, fusing pipe and fittings from 2” to 6” (63 mm to 180 mm) across a variety of pressure ratings. Its carriage can be quickly converted from a 4-jaw to a 3-jaw setup without tools, and in especially tight spaces, the top jaws can be removed with a simple pin release.

Lightweight yet durable, the Acrobat is easy to carry from joint to joint. Its compatibility with either the EP800AD HPU or the more powerful EP1500AD HPU ensures the right performance for every job. With intuitive pressure presets and seamless DataLogger integration, the Acrobat delivers precision fusion and complete data gathering, making it one of the most operator-friendly and future-ready solutions in McElroy’s lineup.

Actionable Data with McElroy Vault

The McElroy Vault™ delivers actionable data by capturing real-time fusion records and transforming them into insights that support compliance and risk management. Every fusion is securely stored and analyzed in one central location, ensuring full visibility and traceability across all jobs.

By combining data from your DataLoggers, the Vault enriches joint reports with details such as operator, machine, and jobsite information, making it easy to sort, review, and verify quality standards. By archiving this documentation, the Vault ensures compliance, reduces risk, and provides proof of performance your teams can trust.

Fusion Solutions for Every Job

While the iSeries and Acrobat machines showcase McElroy’s latest technology, the full fusion lineup spans the complete range of small- and medium-diameter applications. From compact, hand-operated units for confined spaces to larger, track- or wheeled-mounted machines for demanding jobsites, there’s a solution for every pipe size and project requirement.

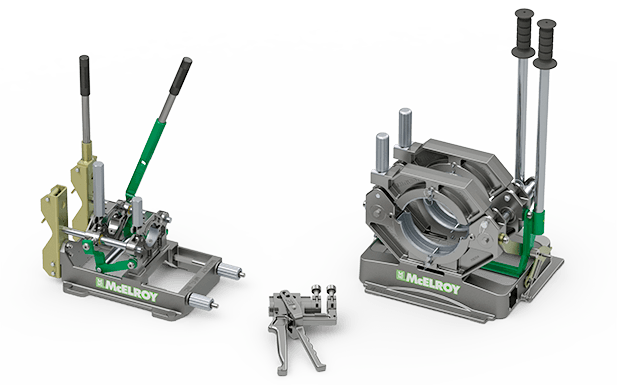

Hand-Powered Machines for Small-Diameter

McElroy’s small-diameter fusion machines handle pipe from ½” CTS to 6” DIPS, combining precision, portability, and consistent performance in durable, single-operator units.

- Mini-Mc®: 1/2" CTS to 1” IPS pipe

- 1LC: 1/2" CTS to 1” IPS pipe

- 2CU: 1/2" CTS to 2” IPS pipe

- 2LC: 1/2" CTS to 2” IPS pipe

- Pit Bull® 14: 1" IPS to 4” DIPS pipe

- Pit Bull® 26: 2" IPS to 6” DIPS pipe

- Acrobat™ 180: 2" IPS to 6" DIPS pipe

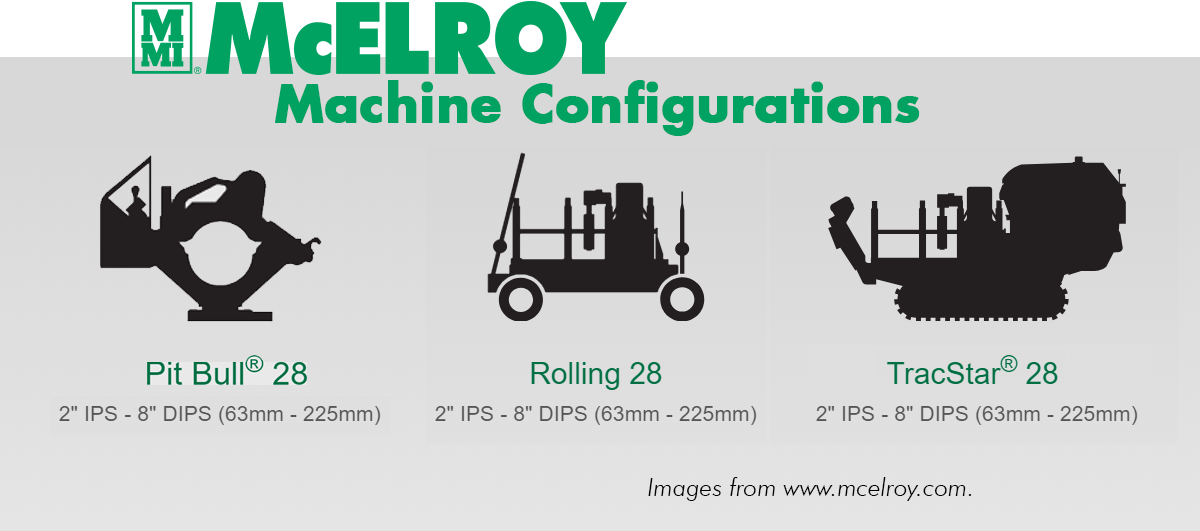

Multiple Configurations for Medium-Diameter

McElroy’s medium-diameter fusion machines handle pipe from 2” IPS to 18” OD, providing versatility and reliability in three configurations – Pit Bull®, Rolling, and TracStar®.

- 28 Models: 2” IPS to 8” DIPS pipe

- 412 Models: 4” IPS to 12” DIPS pipe (includes iSeries option)

- 618 Models: 6” IPS to 18” OD pipe (includes iSeries option)

At GROEBNER, we’re here to support all your pipe fusion needs. From flexible medium-diameter solutions to lightweight, portable small-diameter machines and data-driven performance with the Vault™, our team is ready to help. Contact us today to learn more about McElroy’s innovative equipment, request a quote, or see how we can equip your next project with smarter, safer, and more reliable fusion technology.